CITIZEN CINCOM L20

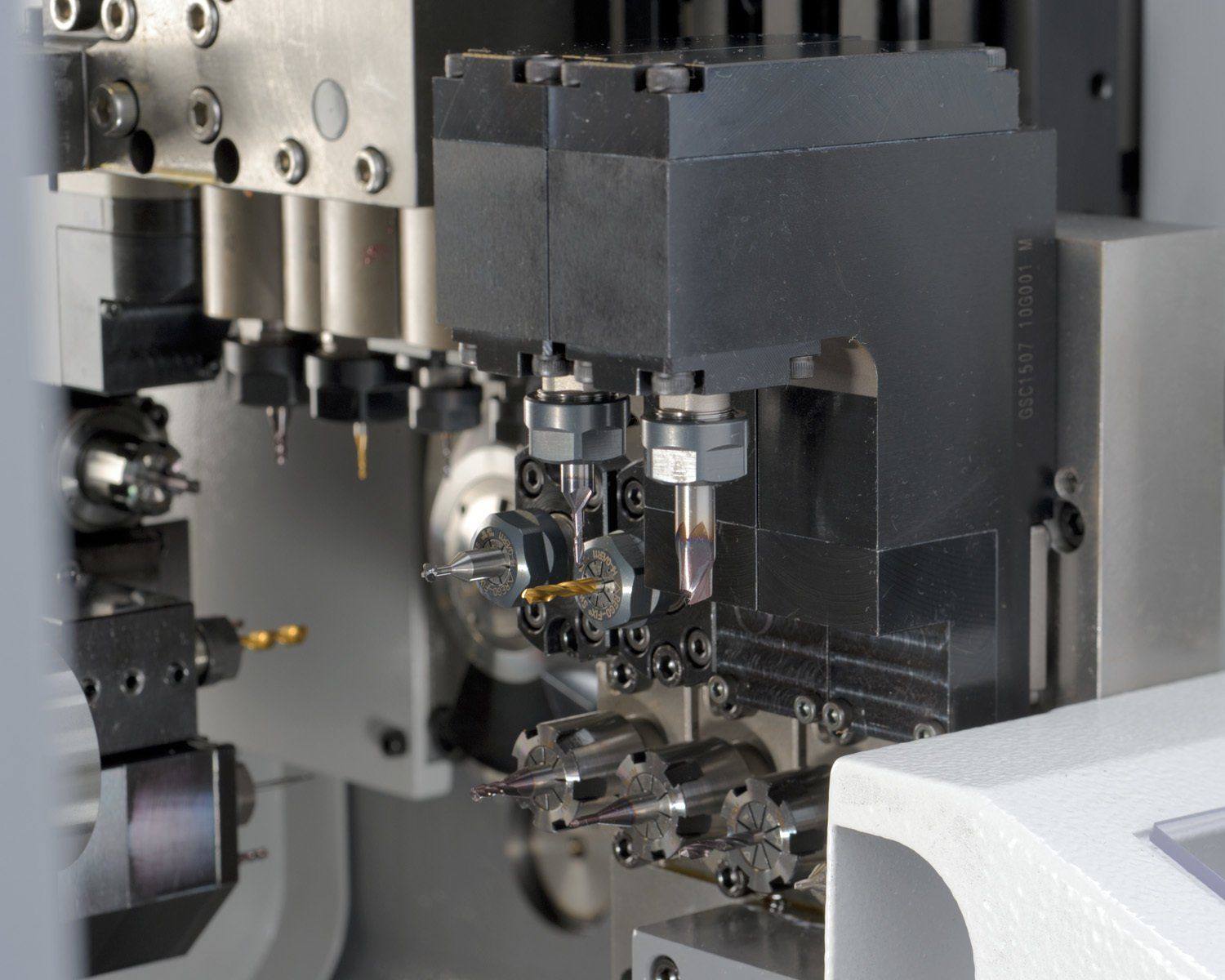

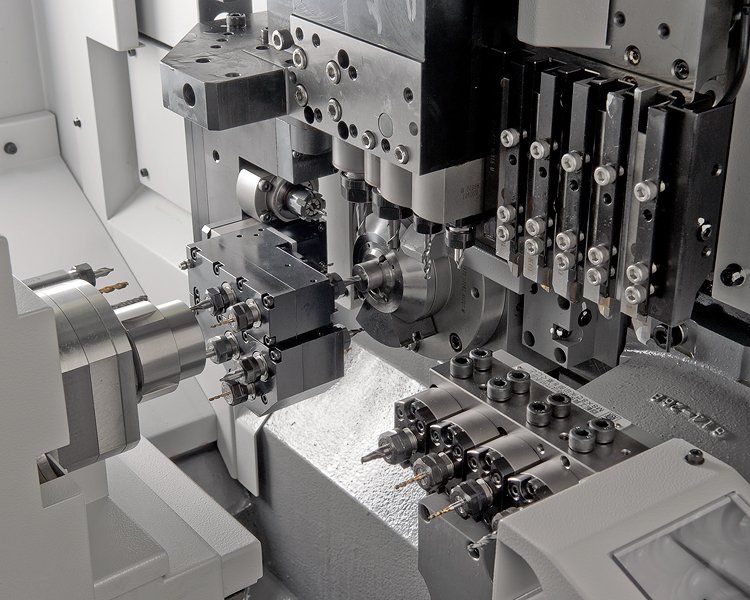

The newest Citizen CINCOM L-series lathes truly must be seen to fully appreciate their speed and tooling flexibility. This latest generation of L20 machine – the L220 - is far more advanced than previous L-series lathes.

The versatile L20-series is equipped with the powerful Mitsubishi Meldas M70LPC-VU control for high-speed processing. Full servo axes and advanced technologies enable faster machining operations while reducing non-cutting idle time by 40% compared to previous models. The L220-series has the ability be converted between guide bushing and non-guide bushing mode. This allows the machine to be used in guide bushing mode for long and small diameter workpieces. Once the guide bushing is removed, it can be used to machine short workpieces with less material waste.

There are 3 different versions of the Citizen L220 now available with varying degrees of sophistication to suit your application’s needs. Each model potentially features our new revolutionary Low Frequency Vibration (LFV) chip breaking technology. This exciting new technology facilitates programmable chip control to reduce chip size and break up your chips.

Citizen Cincom L20

The continuing evolution of the industry standard...

The newest Citizen CINCOM L-series lathes truly must be seen to fully appreciate their speed and tooling flexibility. This latest generation of L20 machine – the L220 - is far more advanced than previous L-series lathes.

The versatile L20-series is equipped with the powerful Mitsubishi Meldas M70LPC-VU control for high-speed processing. Full servo axes and advanced technologies enable faster machining operations while reducing non-cutting idle time by 40% compared to previous models. The L220-series has the ability be converted between guide bushing and non-guide bushing mode. This allows the machine to be used in guide bushing mode for long and small diameter workpieces. Once the guide bushing is removed, it can be used to machine short workpieces with less material waste.

There are 3 different versions of the Citizen L220 now available with varying degrees of sophistication to suit your application’s needs. Each model potentially features our new revolutionary Low Frequency Vibration (LFV) chip breaking technology. This exciting new technology facilitates programmable chip control to reduce chip size and break up your chips.

Typical Parts

Watch the Citizen Cincom L20 in Action!

Contact Us

27101 East Oviatt Rd., Suite 8, Cleveland, OH 44140

Phone: (440)899-9090